Top 5 Conventional Lathe Machines on Alibaba: A Comprehensive Guide

Table of Contents

Are you ready to invest in a top-quality conventional lathe machines but overwhelmed by the vast selection on Alibaba? Worry no more! We’ve done the legwork for you by researching and compiling the top 5 conventional lathe machines on Alibaba to help you make an informed decision.

In this comprehensive guide, we’ll cover the unique features, applications, and price ranges of each machine. So, let’s dive in and explore the world of conventional lathe machines!

Background and Context

A Brief History of Conventional Lathe Machines

Conventional lathe machines have been a staple of the manufacturing industry for centuries. With their ability to perform various tasks, including cutting, sanding, drilling, and turning, these versatile machines have played a crucial role in shaping the modern world.

What Makes a Conventional Lathe Machine Different from CNC Lathe Machines?

While both types of lathe machines perform similar functions, the primary distinction lies in their operation. Conventional lathes require manual control, whereas CNC (Computer Numerical Control) lathes are automated, resulting in increased accuracy and efficiency. However, conventional lathes remain a popular choice for many industries due to their cost-effectiveness and suitability for specific applications.

Top 5 Conventional Lathe Machines on Alibaba

KD DC1880-E Gap Metal Conventional Lathe Machine

The DC1880-E is a horizontal metal turning lathe machine that can handle medium duty machining tasks. It has a spindle bore of 80mm, a spindle speed range of 25-1800rpm, and a spindle motor power of 5.5kw. It can turn workpieces up to 460mm in length and 360/400/460/500mm in diameter. It has a D8 spindle nose and a MT7 spindle taper. It also has a wide bed of 336mm and a distance between centers of 1000mm/1500mm/2000mm/3000mm.

This machine is suitable for various industries, such as building material shops, machinery repair shops, manufacturing plant, food & beverage factory, home use, retail, and construction works. It has a high rigidity and precision, and it comes with a one-year warranty for both the machine and the core components. It also has a new product marketing type and a machinery test report and video outgoing-inspection provided. It is made in Zhejiang, China by KD brand and has a voltage made to order. It has a dimension of 3320x1050x1370mm and a weight of 2900 KG.

Features

| Feature | Value |

|---|---|

| Max. Length of Workpiece (mm) | 460 mm |

| Range of Spindle Speed(r.p.m) | 25 – 1800 r.p.m |

| Machining Capacity | Medium Duty |

| Spindle Bore(mm) | 80 |

| Width of bed (mm) | 336 |

| Max. Turned Length (mm) | 2000 mm |

| Type | Horizontal |

| Spindle Motor Power(kW) | 5.5 |

| Model Number | DC1880-E |

| Voltage | Made to order |

| Dimension(LWH) | 3320x1050x1370mm |

| Weight (KG) | 2900 KG |

| Warranty | 1 Year |

| Key Selling Points | High Rigidity |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Construction works |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Malaysia |

| Marketing Type | New Product 2020 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Bearing, Gear, Gearbox |

| Precision | National Standard |

| Machine Type | Horizontal Metal Turning Lathe Machine |

| Max. Swing Diameter | 360/400/460/500mm |

| Power | 5.5 kw |

| Distance between centers | 1000mm/1500mm/2000mm/3000mm |

| Spindle speed | 25-1800rpm |

| Spindle nose | D8 |

| Spindle bore | 80mm |

Applications

- Turning cylindrical or conical parts, such as shafts, rods, screws, nuts, etc.

- Facing or cutting off the end of a workpiece to make it flat or to a desired length.

- Drilling or boring holes in the center or off-center of a workpiece.

- Threading or cutting grooves on the external or internal surface of a workpiece.

- Knurling or forming a pattern of ridges on the surface of a workpiece for better grip or appearance.

Price Range

The price of the machine depends on the number of sets ordered. The more sets you order, the lower the price per set. Here is the breakdown:

- If you order 1 or 2 sets, the price per set is $10,260.00

- If you order 3 or 4 sets, the price per set is $9,850.00

- If you order 5 or more sets, the price per set is $9,234.00

C6150 Small Manual Conventional Lathe Machine

The C6150 is a small manual conventional lathe machine that can perform various turning operations on metal workpieces. It has a high-strength cast iron bed with a width of 400mm and a quenching depth of 4mm, which ensures stability and durability. It also has a precision-ground spindle box with low noise and high reliability. It can handle workpieces up to 500mm in diameter and up to 4000mm in length. It has a wide range of spindle speeds and feeds, and can cut various metric and inch threads.

This machine is suitable for small and medium-sized workshops, schools, and hobbyists who need a simple and reliable lathe machine. It has a simple structure and easy operation, and it comes with an electromagnetic brake and an electrical safety performance. It also has a one-year warranty and a test report and video inspection provided by the manufacturer. It is made in China by Zaozhuang Shuomai Industrial And Commercial Co., Ltd.

Features

| Specifications for C6150 Lathe Machine | ||

| Capacity | Max.Swing over bed | 500mm |

| Max. rotating diameter | 330mm | |

| Center distance | 750/1000/1500mm | |

| Spindle hole | 52mm | |

| Spindle | Spindle nose | ISO-C6 |

| Spindle tap | MT6 | |

| Spindle speeds(Number) | 36-1400rpm (12 Steps) | |

| Feed | Metric threads range(Kinds) | 0.5-14mm (18 Kinds) |

| Inch threads range(Kinds) | 2-40/inch (28 Kinds) | |

| Moudle threads range(Kinds) | 0.25-3.5mπ (17 Kinds) | |

| Compound rest travel | 150mm | |

| Cross slide travel | 180mm | |

| Cross-section size of toolshank | 20×20mm2 | |

| Tailstock | Dia.of tailstock sleeve | 75mm |

| Taper of tailstock sleeve | MT5 | |

| Travel of tailstock sleeve | 160mm | |

| Main motor power | 5.5KW | |

| Machine size(L*W*H mm) | Overall dimensions for750mm | 2100×1150×1550mm |

| Overall dimensions for1000mm | 2350×1150×1550mm | |

| Overall dimensions for1500mm | 2850×1150×1550mm | |

| Weight(kg) | Weight for 750mm | 1500kg |

| Weight for 1000mm | 1600kg | |

| Weight for 1500mm | 1800kg | |

Applications

- Turning cylindrical or conical parts, such as shafts, rods, screws, nuts, etc.

- Facing or cutting off the end of a workpiece to make it flat or to a desired length.

- Drilling or boring holes in the center or off-center of a workpiece.

- Threading or cutting grooves on the external or internal surface of a workpiece.

- Knurling or forming a pattern of ridges on the surface of a workpiece for better grip or appearance.

Price Range

The price range is $2,000.00 – $5,000.00

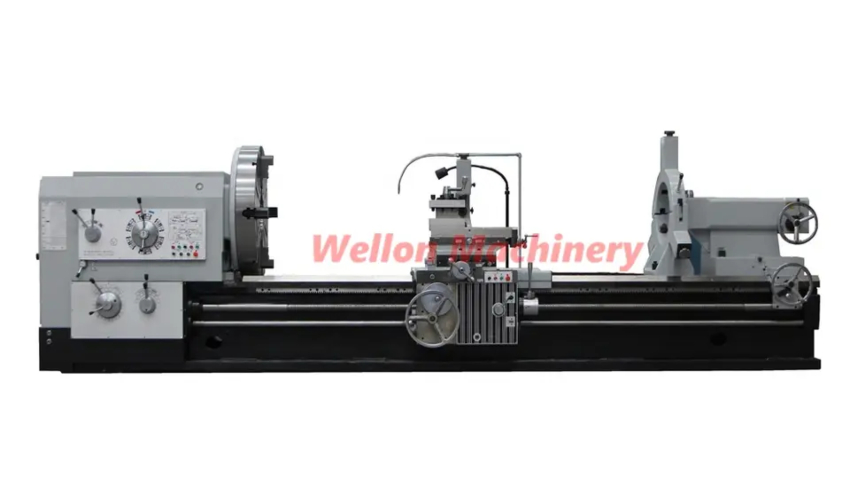

CW61125 Heavy Duty Horizontal Lathe Machine

The CW61125 is a heavy duty horizontal lathe machine that can perform various turning operations on large and heavy workpieces. It has a high-strength cast iron bed with a width of 755mm and a quenching depth of 4mm, which ensures stability and durability. It also has a precision-ground spindle box with low noise and high reliability. It can handle workpieces up to 1250mm in diameter and up to 6000mm in length. It has a wide range of spindle speeds and feeds, and can cut various metric and inch threads.

This machine is suitable for large and medium-sized workshops, factories, and industries that need a powerful and reliable lathe machine. It has a simple structure and easy operation, and it comes with an electromagnetic brake and an electrical safety performance. It also has a one-year warranty and a test report and video inspection provided by the manufacturer. It is made in China by Tengzhou Wellon Machinery Co., Ltd.

Features

| Specifications | unit | CW61125B |

| Max swing over bed | mm | 1250 |

| Max swing over carriage | mm | 850 |

| Center distance | mm | 1500,2000 to 15000 |

| Spindle bore and nose | mm | 130 C15 |

| Spindle taper | mm | MT6 |

| Spindle speed and steps | r/min | CW:21 steps 3.15-315CCW: 12 steps 5-400 |

| 4 jaw chuck diameter | mm | 1000 |

| Longitudinal feed and range | mm/r | 56kinds 0.1-12 |

| Traverse feed and range | mm/r | 56kinds 0.05-6 |

| Rapid moving speed | mm/min | 3740 |

| Lead screw pitch | mm | 12 |

| Metric thread | mm | 44kinds 1-120 |

| Inch thread | t/in | 31kinds 28-3/8 |

| Module thread | mm | 45kinds 0.5-60 |

| Diametral pitch thread | DP | 30kinds 56-1 |

| Cross slide travel | mm | 520 |

| Top rest travel | mm | 300 |

| Tool post | 4 positions | |

| Tool shrank size | mm | 45X45 |

| Tail stock sleeve dia | mm | 140 |

| Sleeve travel | mm | 300 |

| Sleeve taper | MT6 | |

| Main motor power | kW | 22 |

| Rapid feed motor power | kW | 1.5 |

| Coolant pump motor power | w | 125 |

| Machine width and height | mm | 2000X1930 |

| Machine length | ||

| 1500 | mm | 4600 |

| 3000 | mm | 6100 |

| 4000 | mm | 7100 |

| 5000 | mm | 8100 |

Applications

- Turning cylindrical or conical parts, such as shafts, rods, screws, nuts, etc.

- Facing or cutting off the end of a workpiece to make it flat or to a desired length.

- Drilling or boring holes in the center or off-center of a workpiece.

- Threading or cutting grooves on the external or internal surface of a workpiece.

- Knurling or forming a pattern of ridges on the surface of a workpiece for better grip or appearance.

Price Range

According to the search results, the price range for this machine is between $15,000.00 and $10,000.00, depending on the number of sets ordered and the length of work piece.

CS6150 metal lathe machine

The CS6150 is a universal lathe machine that can perform various turning operations on metal workpieces. It has a high-strength cast iron bed with a width of 400mm and a quenching depth of 4mm, which ensures stability and durability. It also has a precision-ground spindle box with low noise and high reliability. It can handle workpieces up to 500mm in diameter and up to 3000mm in length. It has a wide range of spindle speeds and feeds, and can cut various metric and inch threads.

This machine is suitable for small and medium-sized workshops, schools, and hobbyists who need a simple and reliable lathe machine. It has a simple structure and easy operation, and it comes with an electromagnetic brake and an electrical safety performance. It also has a one-year warranty and a test report and video inspection provided by the manufacturer. It is made in China by WMT CNC Industrial Co., Ltd.

Features

| Item | Unit | Parameter | ||

| CS6150 | CS6250 | |||

| Capacity | Max swing over bed | mm | Φ500 | |

| Max swing in gap | mm | Without gap | Φ710 | |

| Effective length in gap | mm | Without gap | 240 | |

| Max swing over slide | mm | Φ300 | ||

| Max workpiece length | mm | 1000/1500/2000/3000 | ||

| Machine bed width | mm | 390 | ||

| Spindle | Spindle thru-hole | mm | φ52 | |

| Spindle nose | ISO 702/Ⅲ No.6 bayonet type | |||

| Spindle speed | r/min | 24 step 9-1600 | ||

| Spindle motor | kW | 7.5 | ||

| Tailstock | Quill dia./travel | mm | φ75/150 | |

| Taper of center | MT | 5 | ||

| Tool post | Number of station/ | 4/25X25 | ||

| Tool section | ||||

| Feed | Max. Travel of upper toolpost | mm | 145 | |

| Max. Travel of lower toolpost | m/min | 320 | ||

| X-axis feed | mm/r | 93 sorts 0.012-2.73 | ||

| Z-axis feed | mm/r | 93 sorts 0.028-6.43 | ||

| Metric thread | mm | 48 sorts 0.5-224 | ||

| Inch thread | t.p.i | 48 sorts 72-1/8 | ||

| Module thread | πmm | 42 sorts 0.5-112 | ||

| DP thread | DP | 42 sorts 56-1/4 | ||

| Others | Coolant pump motor | kW | 0.06 | |

| Machine length | mm | 2632/3132/3632/4632 | ||

| Machine width | mm | 975 | ||

| Machine height | mm | 1230 | ||

| Machine weight | kg | 2100/2300/2500/2900 | ||

Applications

- Turning cylindrical or conical parts, such as shafts, rods, screws, nuts, etc.

- Facing or cutting off the end of a workpiece to make it flat or to a desired length.

- Drilling or boring holes in the center or off-center of a workpiece.

- Threading or cutting grooves on the external or internal surface of a workpiece.

- Knurling or forming a pattern of ridges on the surface of a workpiece for better grip or appearance.

Price Range

The price is $9,800.00

Comparative Analysis: Choosing the Right Machine for Your Needs

When comparing the top 5 conventional lathe machines on Alibaba, it’s essential to consider their features, applications, and price ranges. Each machine has its unique strengths and weaknesses, making them suitable for specific industries and tasks.

- Similarities and Differences: While all five machines offer core lathe functionalities, their specifications and additional features may vary. Consider factors such as size, power, and precision when choosing the right machine for your needs.

- Pros and Cons: Take note of the benefits and drawbacks of each machine, such as ease of use, versatility, and maintenance requirements, to make an informed decision.

- Ideal Machine for Specific Applications: Determine which machine best aligns with your industry and the tasks you need to perform, such as heavy-duty turning, precision work, or small-scale projects.